Ball bearings play a pivotal role in the smooth operation of countless machines and devices. Among these, ceramic ball bearings have emerged as a game-changer. Their unique properties have made them indispensable in various industries. This post delves deep into the advantages, applications, and innovations surrounding ceramic ball bearings.

Understanding Ceramic Ball Bearings

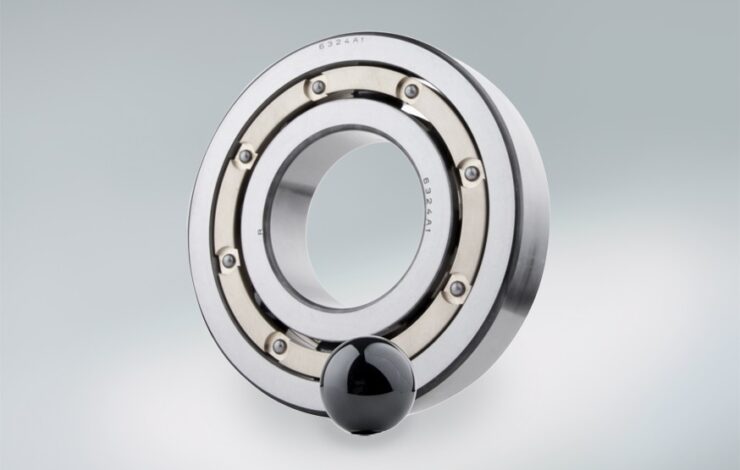

Ceramic ball bearings are not entirely new, but their adoption has surged in recent years. Unlike traditional steel ones, these are made of ceramic materials. Ceramics, known for their high hardness, low friction, and resistance to corrosion, offer distinct advantages over steel. When we talk about ceramics, we’re referring to materials that are neither metallic nor organic. They’re known for their strength and stiffness, and in the case of ball bearings, they offer a performance that often surpasses their steel counterparts.

Advantages of Ceramic Ball Bearings

The benefits of ceramic ball bearings are manifold and have been recognized by various industries:

Reduced Friction and Heat: One of the standout features of ceramic ball bearings is their inherently lower friction coefficient. This reduced friction is not just a minor improvement; it translates to significantly less heat generation during operations. As a result, machines and devices equipped with these items tend to have higher operational efficiency, ensuring that they run smoother and last longer.

Durability: When it comes to longevity, ceramic ball bearings take the lead. Their impressive resistance to corrosion, even in environments where moisture and other corrosive elements are present, ensures they outlast traditional steel. This durability means fewer replacements and disruptions, leading to cost savings in the long run.

High-speed and High-temperature Performance: Ceramic ball bearings are champions in extreme conditions. Whether it’s the high RPMs of a jet engine or the intense heat within an industrial furnace, these remain unfazed. Their resilience in such conditions makes them the preferred choice for applications that demand high speeds or operate at elevated temperatures.

Minimal Maintenance: Another significant advantage is the reduced wear and tear they experience. This inherent property means that ceramic ball bearings require less frequent maintenance. For businesses, this translates to fewer downtimes, reduced labor costs, and an overall more efficient operation.

Types of Ceramic Materials Used

The world of ceramic ball bearings is diverse, with several materials making the cut:

Silicon Nitride: This material stands out for its exceptional resistance to wear. Its lightweight nature makes it a favorite, especially in applications where weight can influence performance, such as in aerospace components.

Zirconia: When strength and toughness are the order of the day, zirconia comes into play. Its robust nature ensures that they’re made from it can withstand considerable stress and strain.

Alumina: Alumina is renowned for its extreme hardness, making it resistant to wear even in the most demanding conditions. This property ensures that bearings made from alumina have a prolonged operational life.

Each of these materials is chosen based on specific needs. For instance, the lightweight nature of silicon nitride makes it a prime choice for high-speed applications where reducing inertia is crucial.

Applications in Various Industries

Ceramic ball bearings are not just a fad; they’re revolutionizing multiple sectors:

Aerospace: In the demanding world of aerospace, these bearings are making a mark. Their ability to withstand the high temperatures found in jet engines and spacecraft ensures improved performance and safety.

Automotive: The automotive industry is always in pursuit of efficiency. By reducing friction, ceramic ball bearings play a pivotal role in enhancing engine efficiency. This improvement also has environmental benefits, contributing to reduced emissions.

Medical: Precision is paramount in the medical field. The accuracy and reliability of ceramic ball bearings make them ideal for medical instruments. Their biocompatibility also opens doors for their use in implantable devices.

Industrial: The industrial sector is reaping the benefits too. Whether it’s high-speed machinery, water pumps, or electric motors, these bearings ensure smoother operations, leading to increased productivity and reduced maintenance costs.

Innovations in Ceramic Ball Bearings

The ceramic ball bearing industry is dynamic, with innovations emerging regularly:

Nanotechnology: The integration of nanotechnology in ceramic manufacturing is groundbreaking. By manipulating materials at the molecular level, manufacturers are producing bearings that are stronger and more durable than ever before.

Smart Sensors: The future is smart, and so are ceramic ball bearings. With integrated sensors, these bearings can provide real-time monitoring, ensuring that any deviations in performance are immediately detected and addressed.

3D Printing: The advent of 3D printing technology has opened new doors. Custom ceramic bearings tailored for specific applications can now be printed, ensuring a perfect fit and optimized performance.

Challenges and Limitations

They often come with a higher price tag than their steel counterparts, making initial investment costs higher. Their inherent brittle nature, a characteristic of many ceramics, means they can be susceptible to breakage under extreme loads. This fragility also means they require specialized handling and expertise during installation to prevent premature failures.

Maintenance and Care

It’s crucial to handle them with utmost care during installation, ensuring that no undue stress is placed on them. Using the recommended lubricants can extend their life and enhance their performance. Regular monitoring techniques, including vibration analysis and temperature checks, can ensure they’re performing at their best, leading to early detection of potential issues.

Case Studies: Real-World Applications

The real-world benefits of ceramic ball bearings are undeniable. In the aerospace industry, for instance, their use has led to more efficient and safer jet engines, translating to significant cost savings. Meanwhile, in the automotive sector, they’re at the forefront of the push for greener, more efficient vehicles, helping reduce the carbon footprint.

Future Prospects and Trends

The ceramic ball bearings industry is on an upward trajectory. The relentless demand for efficiency and performance is driving innovation at an unprecedented rate. Research in material science is leading to the development of even stronger ceramics, promising even better performance. Furthermore, the trend of integrating ceramics with other materials to create hybrid bearings offers the best of both worlds, combining the strengths of both materials.

Selecting the Right Ceramic Ball Bearing

Consider factors such as load capacity, which determines the amount of weight the bearing can handle. Speed requirements are also vital, especially for applications like jet engines or high-speed machinery. The operating conditions, including temperature and environment, play a role in the selection process. Always consult with experts and manufacturers to ensure you’re making an informed choice, tailored to your specific needs.

Conclusion

Ceramic ball bearings, with their myriad advantages, are playing a crucial role in technological advancements across industries. Their potential for continued innovation and growth is undeniable. As industries evolve, the importance of these bearings will only magnify, making them a cornerstone of modern machinery and devices.